Table of Contents

PART 2.

Practical dos and don’ts for different applications

In this article you will find detailed information about what specifications and features to consider when selecting a Touch Sensor IC.

Topics covered from an engineer’s perspective:

- Benefits of selecting industrial-grade touchscreen controllers

- Design considerations for high-immunity touch panels

- Challenges to overcome in medical and industrial applications

- Customization and testing to pass all certifications

- Practical cases and common problems to avoid

Why choosing industrial-grade as standard is worth it

When designing touchscreens for various applications, one of the principal considerations is whether to use an industrial-grade controller or a consumer-grade one. At Riverdi, we recommend and produce only with industrial controllers, recognizing the numerous challenges that can arise with other options. The selection of a suitable controller is crucial, especially in environments with extreme conditions and high requirements.

Design considerations for high-immunity touch panels

In addition to the touchscreen controller, several other R&D phase design elements must be carefully reviewed. This includes  grounding and flexible printed circuit (FPC) design. All this must withstand electrostatic discharge (ESD) tests. By ESD we mean a sudden flow of electric current between two differently charged objects that can affect the proper operation of the device by turning it off or resetting it. For instance, many of our medical field customers require touchscreens that can handle up to 15 kV of air discharge and 8 kV of conducted discharge. These high thresholds demand rigorous design and testing protocols to ensure devices operate safely and reliably during and after such events.

Typical requirements for medical applications

| Parameter | Requirement |

| Air Discharge ESD | 15 kV |

| Conducted Discharge ESD | 8 kV |

| Operational Continuity | Must function continuously or recover automatically |

Key touch panel design features for medical and industrial applications

- Controller selection:

Always select industrial-grade components. - Grounding and FPC design:

Ensure high immunity to electrostatic discharge. - Sensor design:

Customize the design to meet specific application requirements like waterproofing, working with gloves, multi-touch or single-touch functionality or thicker glass.

Challenges in medical and industrial applications

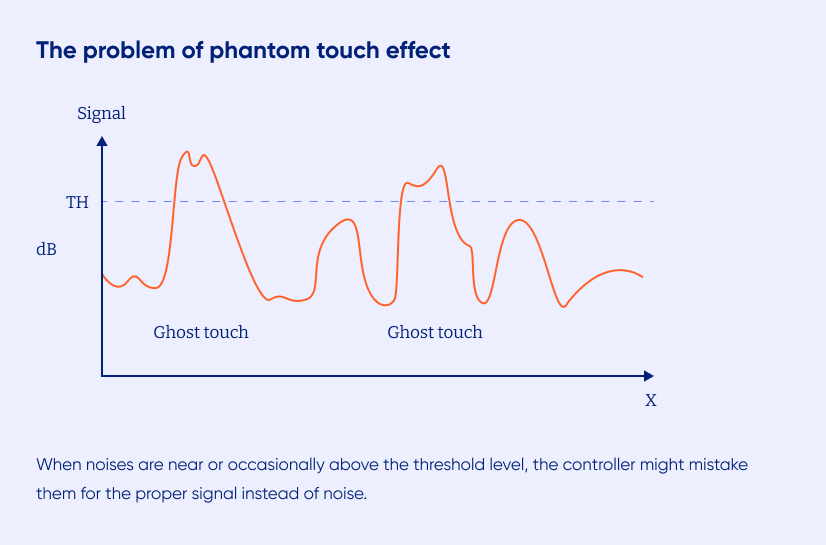

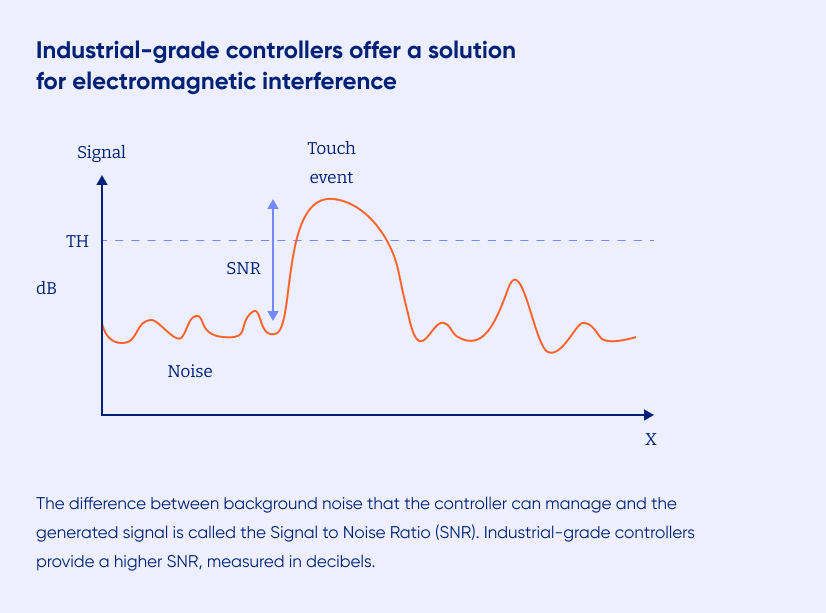

Medical and industrial applications present unique challenges. For instance, medical devices often need to pass certification standards that include rigorous electrostatic discharge requirements. Similarly, industrial environments such as manufacturing sites can have high levels of electromagnetic noise, which consumer-grade touchscreens cannot handle effectively. This can result in false touches or “ghost touches†that may lead to significant safety risks.

Customization and completing even the most demanding certifications

To meet these rigorous standards, our touchscreens and displays are designed with specific considerations from the start. This ensures that even Riverdi’s standard products, with minor customizations, can pass demanding certification processes. For example, industrial applications often require displays that function under extreme conditions, including exposure to water or chemical substances, use with thick gloves and vandal-proof glass. Adding thicker glass or trying to meet certification standards at late design or production phase may involve costly and time-consuming revisions.Â

Steps to ensure certification

Initial Design:

Integrate your industry standards and features (like high ESD immunity) from the beginning.

Testing:

Perform rigorous tests to meet specific industry standards.

Customization:

Adjust designs to the needs identified during testing and to meet certification requirements.

Practical examples and common problems to avoid

Customers often approach us with problems arising from using consumer-grade touchscreens in industrial settings. For example, a touch screen might work well in a controlled laboratory environment but fail during certification due to inadequate controller and sensor design. Similarly, needing to upgrade to vandal-proof glass can involve a complete redesign from the start if the initial consumer-grade controller in most cases cannot support thicker glass.

How to solve common problems

| Problem | Solution |

| Certification failure | Use industrial-grade components |

| Inability to support thicker glass | Select appropriate, industrial-grade controller |

| Touch events in electromagnetic high-noise environments | Ensure proper grounding and shielding |

Selecting the right touchscreen technology is critical for the success of your application. At Riverdi, we offer a range of standard products designed with industrial-grade components, ensuring high performance and reliability. If you need assistance in selecting relevant technology or are facing issues with your current touchscreens, our experts are available to help.

CHECK RIVERDI’S PRODUCTS WITH TOUCHSCREENS

Be sure to find the right industrial-grade touchscreen for your project:

- Need a plug and play HDMI interface and USB-C touch solution?

Pick the HDMI Displays that are high-resolution, high-brightness IPS TFT products with optical bonding and industrial grade touch screen as Riverdi’s standard. - Need to enhance the brightness and optical performance of your device?

Choose High Brightness IPS Displays with optical/air bonding that perfectly reduce the reflection and correct contrast. - In search of the most effective data interchange between graphics and a truly industrial touch controller?

Check BT817Q (EVE 4) product category with revolutionary communication protocol for industrial, medical and military applications requiring beautiful and sophisticated GUI - Looking for one of the highest resolution (1280×800 pixel) HMI displays based on STM32H7 MCUs?

Choose STM32 Embedded Displays with high performance enabled by STM32H757XIH6 (2MB Flash, 1MB RAM) microcontroller.

CONTACT US

Contact our expert to dive deeper into the case of Touch Sensor ICs for your project.

Having issues with your current technology? Want to learn about frameworks and our clients’ success stories? We are happy to discuss and assist you with your design and R&D challenges.

Previous: Part 1

Car Charger Adapter,Usb C Car Charger,Car Phone Charger,Mini Usb Charger, USB Socket

Dongguan Andu Electronic Co., Ltd. , https://www.autoido.com